Climate impact

In Finland, municipalities in the Turku region teamed up to build a new facility to treat the waste water of the area’s 300,000 inhabitants. The facility includes two 21 MW heat pumps that capture heat from the cleaned waste water and feed 85-degree water to the district heating network. The heat pumps also produce district cooling.

The climate impact depends on the carbon footprint of the electricity used by the heat pumps and the heat generation it replaces. The Turku facility produces 302 GWh of heat a year – enough for 24,000 inhabitants, or 8% of the residents in the area from which the waste water is collected. The heat has mainly replaced burning oil and coal, which is estimated to have reduced emissions by 80 ktCO2.

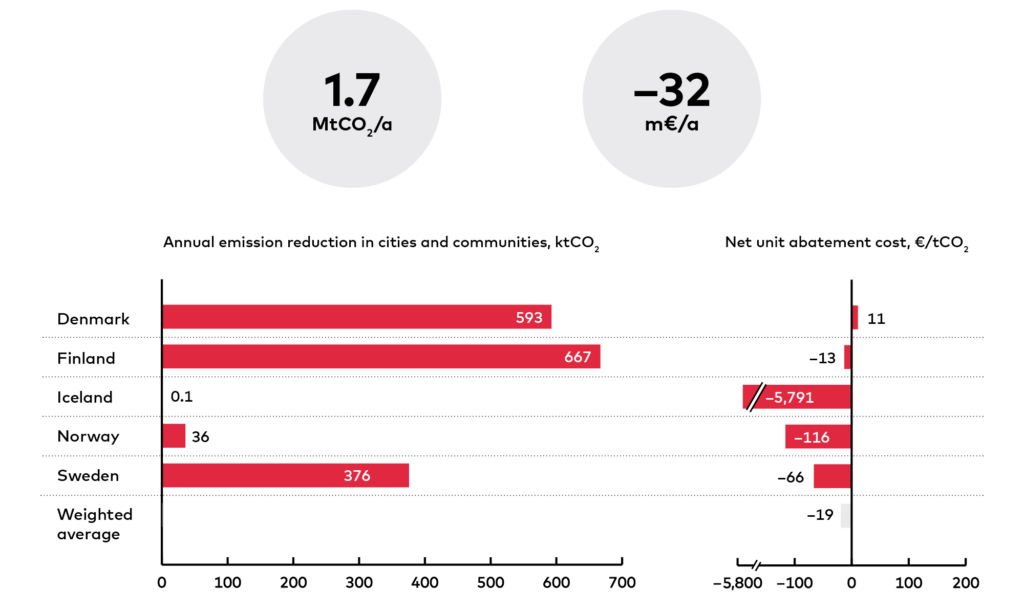

If all the Nordic municipalities with district heating captured their waste-water heat and produced 8% of their district heat with it, it could replace 5.7 TWh of fossil heat production and reduce emissions by 1.7 MtCO2.

Costs and savings

The total cost of heat energy captured from waste water depends mainly on the investment cost, the efficiency of the pump and the cost of electricity for the heat pumps. As heat pumps often do not fully replace a heat or cogeneration plant in the district heating network, we compare the heat pump cost to the variable cost of thermal plants. We estimate the weighted average abatement cost in the Nordics to be –19 €/tCO2. The cost varies between the Nordic countries as a result of the differing taxes applied to heat pump electricity.

Other benefits

Replacing fuel combustion with heat pumps cuts air pollution.

It also reduces the need for importing fossil fuels and increases energy security. Heat pumps can be used to provide flexibility to the energy system – instead of ramping up a fossil power plant, the heat pumps can be switched off during a power demand peak.

The new treatment plant has also brought other benefits in Turku. The improved water purification has reduced the nutrient load on the vulnerable sea ecosystem nearby. The recycled fertilisers produced from waste-water sludge reduce the need for virgin fertiliser production, increase the sufficiency of the limited supply of mined phosphorus and avoid emissions of ammonia and nitric acid production, two key inputs for nitrogen fertilisers.

Barriers

- The heat source needs to be located close to the end users so that the investment in the extended pipe infrastructure and heat losses do not become too large, but there might be limited space for a water treatment facility in a city.

- The facility also requires a significant amount of electricity, so the electricity grid in the desired location must be strong enough or it must be fortified, which adds costs.

- The initial investment for the heat pump facility is often large, and therefore the heat pumps require a sufficient number of load hours to keep the price of the heat down. In some networks this may be restricted by the existing heat production system.

- The required district heating water temperature in winter may be higher than can be provided by heat pumps and the heat requires priming. If this cannot be done with existing facilities, it can become expensive.

- The price of the main input, electricity, can limit the profitability of the investment.

Enablers

- Waste water as a heat source is free, stable and predictable. It is naturally located close to heat users. In Turku’s case, the treatment plant was built underground within the city.

- Enough use hours, relatively inexpensive electricity and high fossil fuel taxes make heat pumps profitable.

- Low network temperature allows the heat to be used without priming. In Turku, no priming of the 85-degree heat is needed.

RELATED SOLUTIONS